Ever thought about the unsung heroes of the mining industry? No, it's not the hard-working miners or the gleaming machinery, it’s actually the polymers! 🎉 In the world of tailings treatment, polymers are stepping into the spotlight, and let me tell you, they’re putting on quite a show!

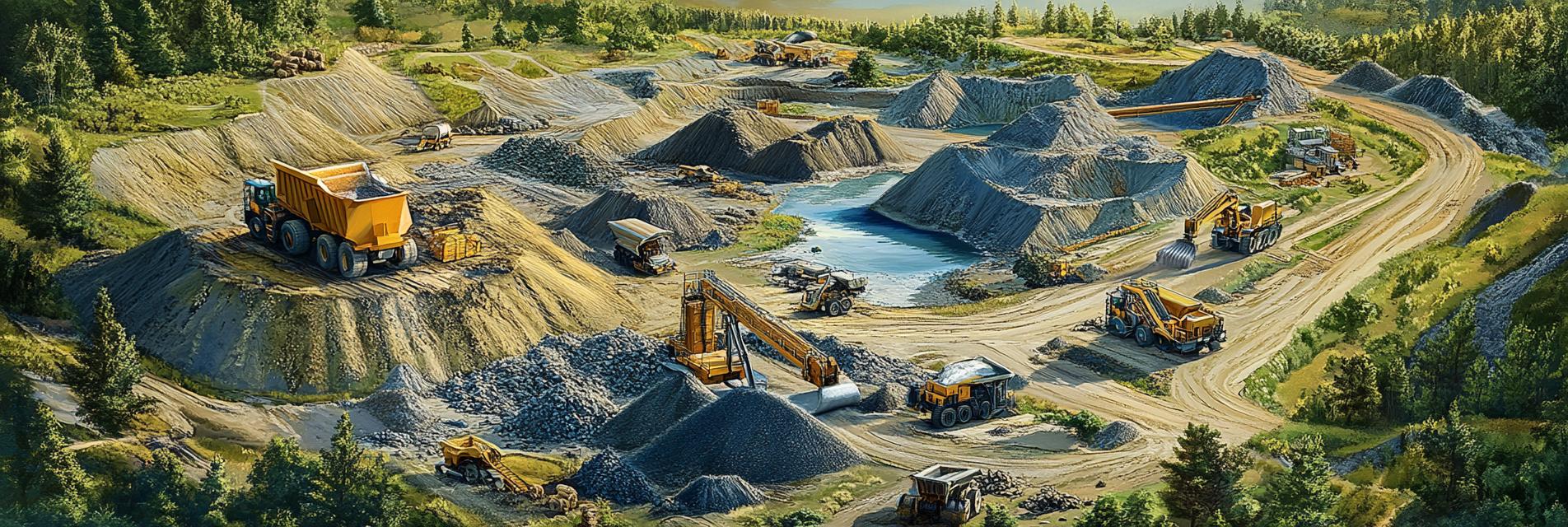

Tailings, for those who don’t spend their evenings sifting through mining journals, are what’s left over after the valuable materials have been extracted from ores. Think of them as the leftovers after a birthday party – not very appetizing and quite the environmental headache if not managed properly! 🍰

Now, let’s get to the fun part! Polymers are long-chain molecules that can significantly enhance the efficiency of tailings treatment. The innovative applications of these polymers improve water recovery and reduce the environmental footprint – talk about a win-win situation!

1. The Green Mining Initiative: A leading mining firm in Australia recently integrated polymer treatment into their tailings management process, resulting in a 35% decrease in water waste. Now that's what I call partying responsibly! 🎈

2. Rio Tinto's Polymer Application: This global giant implemented a polymer that not only enhanced the settling rates of tailings but also drastically reduced the amount of chemical reagents needed in the process. Their eco-friendly approach received accolades in the industry and maybe even a few green thumbs up! 👍

As we continue to innovate and fulfill our environmental responsibilities, the successful application of polymers in tailings treatment demonstrates a proactive approach to sustainable mining practices. By adopting these technologies, we not only enhance efficiency but also protect the environment for future generations. 🌱

So, next time you think about tailings management, remember: it’s not just waste, it’s a potential treasure trove of efficiency and sustainability! Let’s raise our glasses (or hard hats) to polymers making the mining world a greener place! 🥳