As a seasoned professional in the realm of rubber manufacturing, I can tell you that high-temperature vulcanization (HTV) isn’t just a fancy term thrown around in industry meetings. It’s a magical process that can transform rubber from a simple, stretchy material into a durable and versatile product that has applications in various industries. 🧙♂️

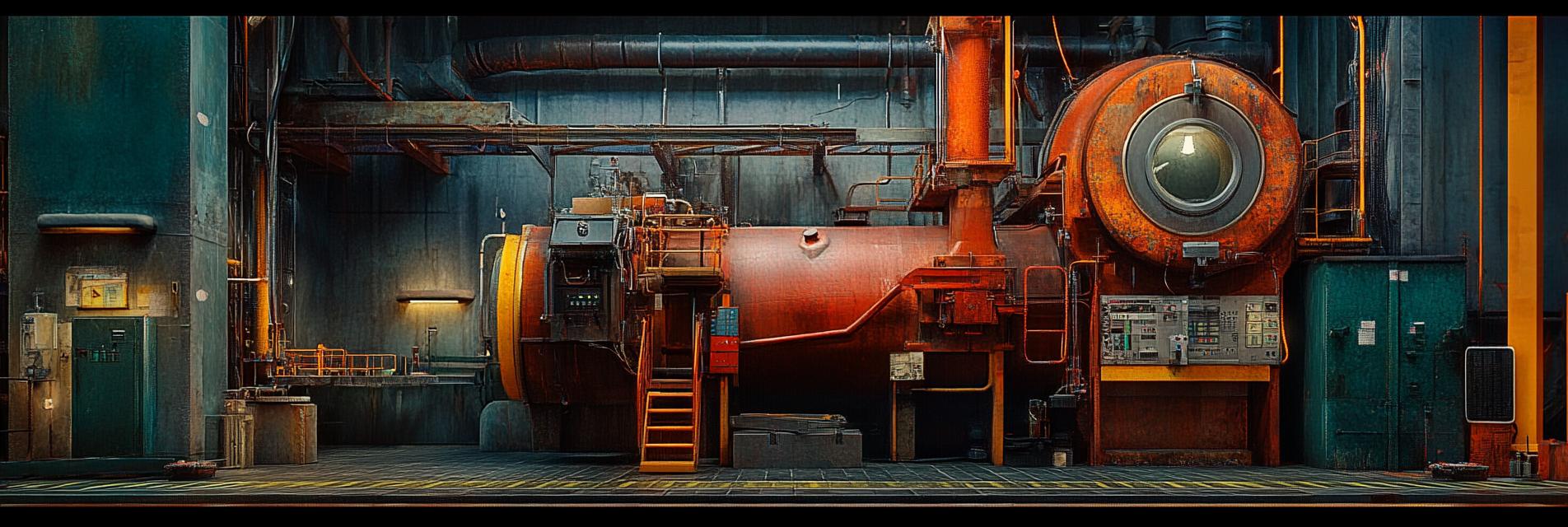

HTV refers to the process of vulcanizing rubber at elevated temperatures, typically between 140°C to 180°C. This method enhances the material properties of rubber, making it more resilient and heat-resistant. Imagine rubber being molded and twisted into shape, only to undergo a heat treatment that bestows upon it a robust character, much like a superhero gaining powers! 💪

The HTV process usually involves several key steps:

This all happens while I sip my coffee and visualize the perfect rubber product being created! ☕

So, why choose HTV over other methods? Here’s why:

With all these benefits, who wouldn’t want to get on the HTV bandwagon? It’s like having a secret sauce that makes your rubber products stand out in the crowded market.

Here’s the exciting part – HTV is applied in numerous sectors:

In every corner, the HTV technique plays a pivotal role in enhancing the materials that keep our world running smoothly!

In conclusion, high-temperature vulcanization is a powerful technique that revolutionizes rubber manufacturing. It’s not just a process; it’s a way to elevate our products to meet the highest industry standards. As I wrap up this comprehensive guide, I can’t help but feel excited about the endless possibilities that HTV offers. Now, let’s get rubbery! 🏭